The RAZORBLADE is a non-explosive, reliable and cost-efficient punching tool which can punch single or multiple holes in a single run and operates as a Plug & Play add on to the RAZORBOSS Plug & Play platform of tools. The RAZORBLADE tool delivers circulation holes in a range of tubing and casing sizes from 2-7/8” to 9-5/8” and does not damage the outer or annular pipe string. RAZORBLADE also has the ability to create centralisation or standoff between tubing and casing or casing to casing enhance cement placement.

RAZORBLADE utilises the RAZOR Control Module (RCM), a disposable alkaline battery pack for power requirements and which delivers a single punching operation per pack. The alkaline pack is easy to handle, easy to transport, recyclable and is wellsite safe. RAZORBLADE can be run in real time or memory mode and is suitable for use with all conveyance methods including mechanical slickline, real time slickline, electric line, coiled tubing, sucker rod or jointed work string. The RAZORBOSS platform records voltage, current, status, time and temperature for quality-assurance purposes.

Features and Benefits

- Non-Explosive/Non-Lithium which improves safety, handling, and logistics

- Rugged, reliable, and efficient punching tool

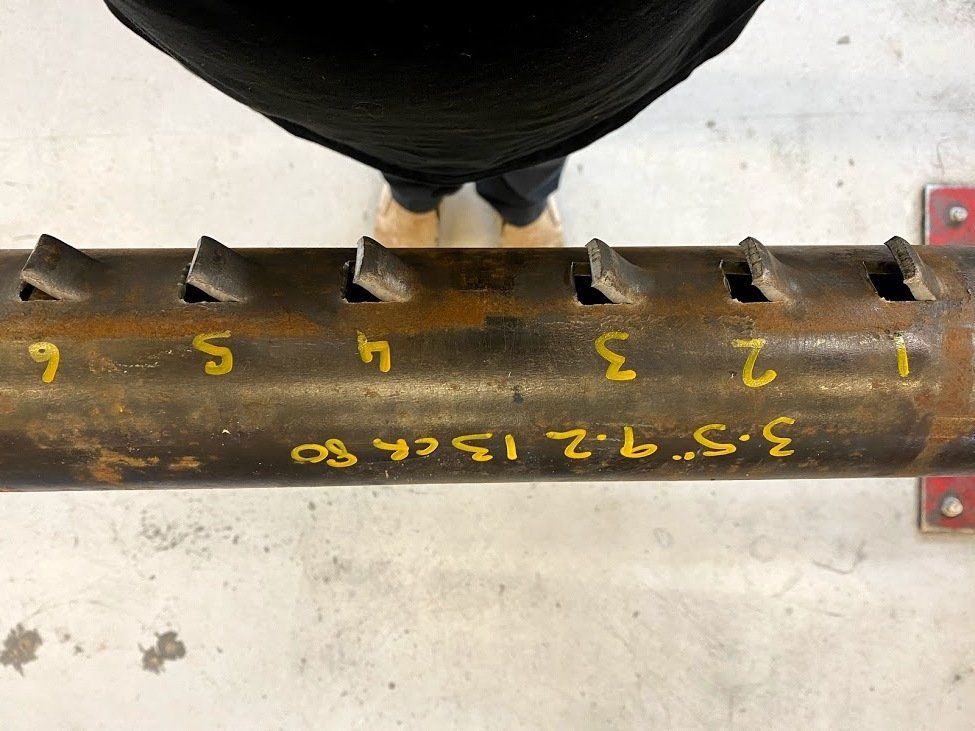

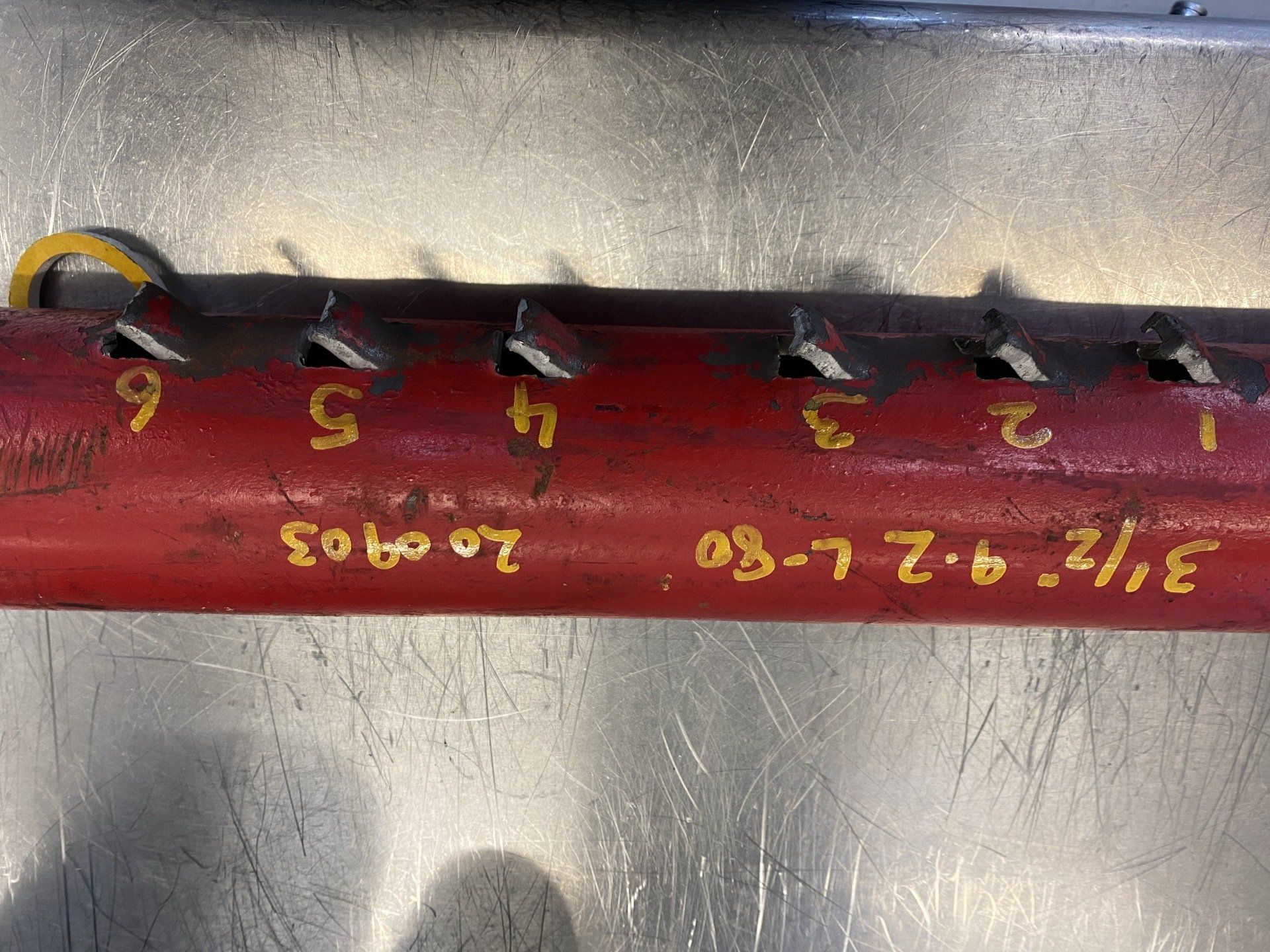

- Punches 1-6 holes in a single run into the wellbore

- Contains a safety shear out mechanism

- Can be anchored to prevent being blown up hole

- Can be activated real time or memory timer

- Acceleration feature to abort service

- Short, light weight design aids in mobilization via winged aircraft or helicopter

- Ideal for operations with limited rig up height i.e., rig-less operations

- Tool electronics are changed each run ensuring quality and reliability

- High temperature tool qualified to 437˚F for 6 hours

Applications

- Tubing/Casing punch for circulation

- Tubing/Casing punch for squeeze cementing

- Limited entry - punch inner pipe without damaging outer or annular string

- Punching Sand Screen base pipe

- Single or multiple punches for pressure equalisation

- Pipe centralisation for improved flow or cementation

- Single Run Plug & Punch when combined with RAZORBOSS & RAZORSET

Specifications

| Tubing Size | 2.875” | 3.500” | 4.500” | 5.000” | 5.500” | 7.000” | 9.625” |

|---|---|---|---|---|---|---|---|

| Tool Length | 56.94” | 66.61” | 66.51” | 60.88” | 61.11" | 94.52” | 93.92” |

| Tool Weight | 40.39 lbs | 77.75 lbs | 147.64 lbs | 147.64 lbs | 147.64 lbs | 222.18 lbs | 272.12 lbs |

| Max Pressure | 15,000 psi | 15,000 psi | 15,000 psi | 15,000 psi | 15,000 psi | 15,000 psi | 15,000 psi |

| Standard Temp | 275˚F for 6 hours | 275˚F for 6 hours | 275˚F for 6 hours | 275˚F for 6 hours | 275˚F for 6 hours | 275˚F for 6 hours | 275˚F for 6 hours |

| Hi Temp | 437˚F for 6 hours | 437˚F for 6 hours | 437˚F for 6 hours | 437˚F for 6 hours | 437˚F for 6 hours | 437˚F for 6 hours | 437˚F for 6 hours |

| Tubing Grade | J55 to P110 | J55 to P110 | J55 to P110 | J55 to P110 | J55 to P110 | J55 to Q125 | J55 to P110 |

| Tubing Weight | 6.4 to 8.6 | 7.7 to 10.2 | 11.6 - 15.1 | 18 to 20.3 | 17.0 - 26.0 | 23.0 - 38.0 | 47.0 - 53.0 |

| Punch Head OD | 2.16" | 2.720” | 3.600” | 3.800” | 4.400” | 5.600" | 8.350” |

| Holes Per Run | 1 to 6 | 1 to 6 | 1 to 6 | 1 to 6 | 1 to 6 | 1 to 6 | 1 to 3 |

| Hole Size | 0.43" | 0.65" | 0.73" | 0.73" | 0.95" | 0.95" | 0.95" |

| Hole Flow Area | 0.14 in² | 0.33 in² | 0.42 in² | 0.42 in² | 0.70 in² | 0.70 in² | 0.70 in² |

| Top Connection Slickline | 1 1/16” - 10 UN Sucker Rod | 1 1/16” - 10 UN Sucker Rod | 1 1/16” - 10 UN Sucker Rod | 1 1/16” - 10 UN Sucker Rod | 1 1/16” - 10 UN Sucker Rod | 1 1/16” - 10 UN Sucker Rod | 1 1/16” - 10 UN Sucker Rod |

| Top Connection Eline | 1 3/16” - 12 UN GO | 1 3/16” - 12 UN GO | 1 3/16” - 12 UN GO | 1 3/16” - 12 UN GO | 1 3/16” - 12 UN GO | 1 3/16” - 12 UN GO | 1 3/16” - 12 UN GO |

| Bottom Connection | 1 1/16” - 10 UN Sucker Rod Box | 1 1/16” - 10 UN Sucker Rod Box | 1 1/16” - 10 UN Sucker Rod Box | 1 1/16” - 10 UN Sucker Rod Box | 1 1/16” - 10 UN Sucker Rod Box | 1 1/16” - 10 UN Sucker Rod Box | 1 1/16” - 10 UN Sucker Rod Box |

Notes:

- Hole quantity and hole size per run varies in heavier weight casing, contact RAZOR for further information.

- Varying Hole size and phasing available for special applications

- Pipe grades that can be punched - J55 - K55 - L80 - N80 - C95 - P110 - 13Cr - 25 Cr

Tubing Flow Area Reference Chart

| Tubing Size | 2.875” | 3.500” | 4.500” | 5.000” | 5.500” | 7.000” | 9.625” |

|---|---|---|---|---|---|---|---|

| Flow Area 1 Hole | 0.14 in² | 0.33 in² | 0.42 in² | 0.42 in² | 0.70 in² | 0.70 in² | 0.70 in² |

| Flow Area 2 Holes | 0.28 in² | 0.66 in² | 0.84 in² | 0.84 in² | 1.40 in² | 1.40 in² | 1.40 in² |

| Flow Area 3 Holes | 0.42 in² | 0.99 in² | 1.26 in² | 1.26 in² | 2.10 in² | 2.10 in² | 2.10 in² |

| Flow Area 4 Holes | 0.56 in² | 1.32 in² | 1.68 in² | 1.68 in² | 2.80 in² | 2.80 in² | |

| Flow Area 5 Holes | 0.70 in² | 1.65 in² | 2.10 in² | 2.10 in² | 3.50 in² | 3.50 in² | |

| Flow Area 6 Holes | 0.84 in² | 1.98 in² | 2.52 in² | 2.52 in² | 4.20 in² | 4.20 in² |